Introduction

- Brief history of jeans

Jeans, a timeless wardrobe staple, have a rich history dating back to the 19th century. Originally designed as durable work pants by Levi Strauss and Jacob Davis, jeans have evolved into a global fashion icon, transcending cultures and generations.

- Importance of fibers in jeans manufacturing

Fibers play a crucial role in the manufacturing of jeans, determining the comfort, durability, and aesthetic appeal of the final product. Understanding the different types of fibers used in jeans manufacturing is essential for both manufacturers and consumers.

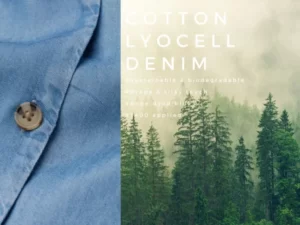

Types of Fibres Used

- Cotton

- Characteristics Cotton, a natural fiber, is known for its softness, breathability, and absorbency. It is also hypoallergenic and comfortable to wear in various climates.

- Advantages: The use of cotton in jeans results in a soft, breathable fabric that is comfortable for everyday wear. It also absorbs dyes well, allowing for a wide range of color options.

- Disadvantages: While cotton is a durable fiber, it is prone to shrinking and wrinkling, requiring special care during washing and ironing.

- Practical examples of jeans made with cotton Popular examples of jeans made with cotton include classic denim styles from brands such as Levi’s, Wrangler, and Lee.

- Denim

- Characteristics Denim is a sturdy cotton twill fabric, typically dyed with an indigo color on the warp yarn and undyed on the weft yarn, creating its distinctive blue color and white underside.

- Advantages: Denim is known for its durability and rugged appearance, making it ideal for casual and workwear. It also becomes softer and more comfortable with wear.

- Disadvantages: One of the drawbacks of denim is its initial stiffness, which can require a “break-in” period for the jeans to conform to the wearer’s body.

- Practical examples of jeans made with denim Iconic denim brands such as Levi’s, Diesel, and Guess offer a wide range of jeans made with denim in various styles and washes.

- Stretch Fibres

- Characteristics Stretch fibers, such as elastane or spandex, are blended with traditional fibers to add flexibility and stretch to the fabric, enhancing comfort and fit.

- Advantages: Jeans incorporating stretch fibers provide enhanced mobility and shape retention, catering to the demand for form-fitting and comfortable styles.

- Disadvantages: While stretch fibers offer improved flexibility, they may reduce the fabric’s breathability and longevity over time.

- Practical examples of jeans made with stretch fibers Contemporary denim brands, including AG Adriano Goldschmied, 7 For All Mankind, and J Brand, are known for offering jeans with stretch fibers to provide a comfortable and flattering fit.

Sustainable Fibres in Jeans Manufacturing

Organic Cotton

When it comes to sustainable fibers in jeans manufacturing, organic cotton has gained significant attention for its environmental and social benefits.

- Benefits of Organic Cotton:

- Reduced Environmental Impact: Organic cotton is cultivated without the use of synthetic pesticides, insecticides, or genetically modified organisms (GMOs), promoting healthier ecosystems and biodiversity.

- Water Conservation: Organic cotton farming practices often emphasize water efficiency, reducing the overall consumption of water compared to conventional cotton cultivation.

- Health and Safety: By eschewing potentially harmful chemicals, organic cotton promotes safer working conditions for farmers and field workers, as well as minimizes exposure to toxic substances for local communities.

- Practical Examples of Jeans Made with Organic Cotton:

- Nudie Jeans: This Swedish denim brand is renowned for its commitment to sustainable practices, including the use of organic cotton in their jeans.

- Kuyichi: A pioneering brand in sustainable denim, Kuyichi offers a range of jeans made with organic cotton, showcasing a dedication to eco-friendly materials and ethical production.

Recycled Materials

Another approach to sustainable fibers in jeans manufacturing involves the use of recycled materials, contributing to the circular economy and reducing the environmental impact of textile production.

- Advantages of Recycled Materials:

- Waste Reduction: Incorporating recycled materials, such as recycled polyester or post-consumer denim, helps divert textiles from landfills and reduces the demand for virgin resources.

- Energy and Resource Conservation: Using recycled materials typically requires less energy and water compared to the production of new fibers, contributing to lower carbon emissions and the conservation of natural resources.

- Practical Examples of Jeans Made with Recycled Materials:

- Reformation: This eco-conscious fashion brand offers a selection of jeans made with recycled cotton and repurposed denim, aligning with their commitment to sustainable and ethical fashion practices.

- Mud Jeans: Embracing a circular model, Mud Jeans utilizes recycled and organic materials in their denim production, offering a range of jeans with a reduced environmental footprint.

These examples illustrate how organic cotton and recycled materials are being integrated into the production of sustainable jeans, reflecting a growing awareness and demand for environmentally responsible fashion choices.

Impact on the Fashion Industry

- Market Transformation

The adoption of sustainable fibers in jeans manufacturing is poised to catalyze a transformative shift in the entire fashion industry. As consumers increasingly prioritize eco-friendly and ethically produced clothing, the demand for sustainable denim is expected to surge. This shift has the potential to influence industry norms and compel fashion brands to reevaluate their sourcing and production practices. Consequently, the widespread adoption of sustainable fibers in jeans manufacturing may lead to a broader reassessment of material sourcing and supply chain processes across the fashion sector, thereby fostering a more sustainable and responsible industry as a whole.

- Innovation and Collaboration

The integration of sustainable fibers in jeans manufacturing is driving a wave of innovation and collaboration within the fashion industry. Textile manufacturers, designers, and brands are coming together to explore new materials, technologies, and production methods that align with sustainability goals. This collaborative spirit is fostering creativity and pushing the boundaries of traditional denim production, paving the way for the development of groundbreaking solutions that uphold environmental and social integrity. From alternative dyeing techniques to water-saving manufacturing processes, the embrace of sustainable fibers is inspiring a renaissance of innovation in jeans manufacturing, ultimately setting new industry standards and spurring positive change.

- Consumer Education and Empowerment

The growing prevalence of sustainable fibers in jeans manufacturing is generating opportunities for consumer education and empowerment. As consumers become more discerning and conscious of their purchasing choices, the fashion industry is compelled to provide transparent information about the materials and processes used in garment production. This shift towards transparency empowers consumers to make informed decisions, encouraging them to support brands that prioritize sustainable fibers and ethical practices. Furthermore, it fosters a sense of environmental stewardship among consumers, prompting them to advocate for greater accountability and sustainability in the fashion industry. As a result, the increasing availability and visibility of sustainable denim options are contributing to a more informed and empowered consumer base, influencing purchasing behaviors and steering the fashion industry towards greater sustainability.

Conclusion

- Summary of Key Points

In conclusion, the use of sustainable fibers in jeans manufacturing presents a promising pathway toward mitigating the environmental impact of the fashion industry. Organic cotton, with its reduced environmental footprint and support for healthier farming practices, has emerged as a leading contender in the quest for sustainable denim. Additionally, the incorporation of recycled materials underscores the potential for a circular approach to denim production, promoting resource conservation and waste reduction. The examples of brands such as Nudie Jeans, Kuyichi, Reformation, and Mud Jeans highlight the growing traction of sustainable fibers in the realm of jeans manufacturing, reflecting a shift towards more eco-conscious and socially responsible fashion choices.

- The Future of Fibres in Jeans Manufacturing

Looking ahead, the future of fibers in jeans manufacturing holds tremendous potential for innovation and progress. As awareness of environmental and social issues continues to permeate consumer consciousness, the demand for sustainable fibers is anticipated to surge. This momentum is likely to drive further research and development into novel fibers and processes that align with the principles of sustainability. With advancements in technology, there is potential for the emergence of new materials that offer enhanced eco-friendly characteristics without compromising on quality or performance. Furthermore, the integration of transparency and traceability in the supply chain is poised to play a pivotal role in shaping the future of fibers in jeans manufacturing, allowing consumers to make informed decisions and hold brands accountable for their sustainability claims.

Overall, the future of fibers in jeans manufacturing holds promise for a paradigm shift towards greater environmental stewardship and ethical practices, laying the groundwork for a more sustainable and conscientious fashion industry.